Wire Grinding from Wytech

In the medical device industry, precision wire types are essential. Making sure that accuracy in measurement is strictly maintained, as well as providing a wide range of products and services, are both important factors when choosing a wire grinding company. When you choose to work with Wytech, you can rest assured that we will adhere to your exacting specifications to provide you with quality components.

Wytech offers the types of wire grinding that your company needs

At Wytech, we pride ourselves on providing a broad spectrum of wire grinding capabilities, so you can count on us to provide you with exactly what you need for your application. Wytech has the technical expertise to provide the medical industry with the precision wire grinding it needs for the best in patient care.

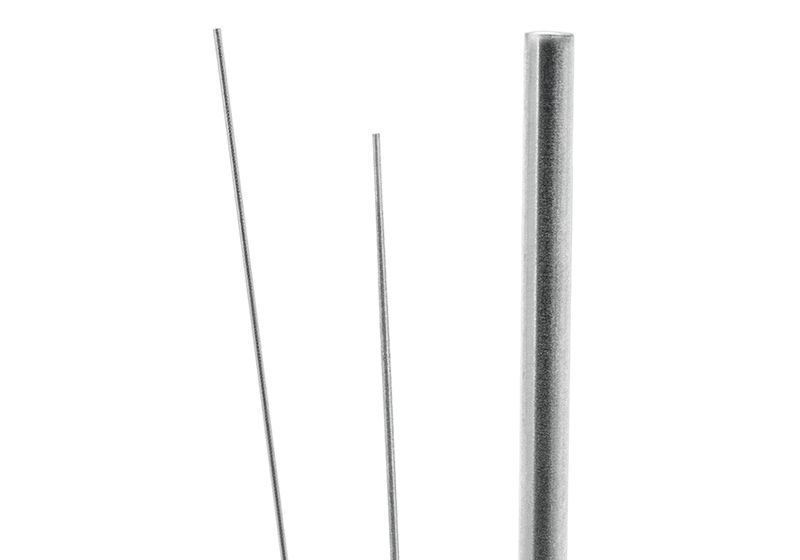

- Centerless Wire Grinding: This provides wire grinding for applications that include guide wires, core wires, and mandrels. Appropriate grinding is required for wire used in these devices, to ensure that the wire is tapered to be optimally stiff, yet flexible, throughout the length of the medical device.

- OD Wire Grinding: Generally speaking, this sort of wire grinding is used for threads, points, and customized profiles such as notches, grooves, steps, bumps, and flats.

Discover how Wytech’s advanced precision grinding technologies can help you

- 0.002” accurate wire positioning

- Grinds of unlimited lengths

- CAM grinding: shape flats, threads, bumps, arcs, hexes, balls, ellipses, and concave/convex radii with linear tolerances as precise as +/- 0.001”

- Flat grinds for “D,” “C,” and crescent-shaped lumen

- Typical Grind Profiles: multi-taper, paddle, plunge for special mandrels, and skiving

- Intricate profile grinds for PTCA Guidewires and Neuro Interventional Guidewires

- Skiving: feature produced typically on Hypotubes to allow for a smooth transition for the tube flexibility in guidewire catheter assemblies

- In-house annealing and stress-relieving for maximum flexibility in processing

- Super abrasive wheels for efficient removal in a variety of alloys

- 450 CM Loader Trays reduce set-up times

- Laser profile gauging systems for quality control

- Secured parts history library on grinding and inspection equipment for seamless setups

Tell Us About Your Product Goals

Featured Products

The FastLane program was developed specifically to provide design engineers fast access to a wide selection of thin wall hypotubes & fine wire sizes, alloys and lubricious coatings for urgent developmental work.

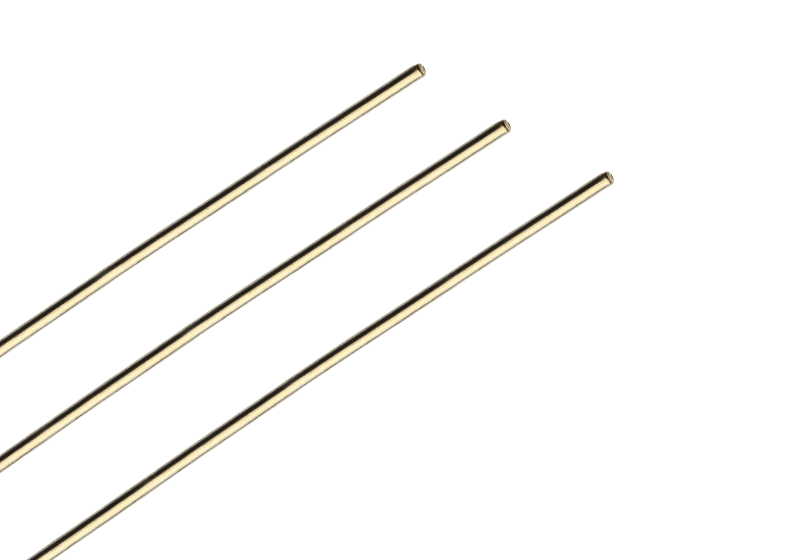

- Medical Wire

- Stainless Steel, Nitinol, PTFE Coated & Parylene Coated Wire

- Diameters ranging from 0.003" - 0.145", half sizes also available

- Available in 60", 73″ and 120″ lengths

- Hypotubes

- Stainless Steel Thin Wall Metal Tubes

- Diameters ranging from 0.009" - 0.112"

- Available in various lengths

- $200 minimum order required

- COC included in each shipment

Whether it’s a product evaluation, evaluating an alternative manufacturing process, or a situation that demands delivery in four weeks, FastTrack meets your needs.

- 100% focus on mandrel and core wire development with specialized equipment and dedicated manufacturing cell

- Precision Centerless Grinding

- Catheter mandrel and core wire development

- Fast delivery, < 4 week

- Dedicated inventory of common medical wire