Medical Wire Straightening & Cutting

Wytech have spent nearly the last 50 years perfecting the art of wire technology to ensure accuracy with the cut, length, and straightness of medical wire.

We're particularly skilled with alloys including a variety of stainless steel, PTFE coated wires and nitinol.

We can provide uncoated and coated metal mandrels for the following manufacturing processes: bonding, coiling, extrusion, forming, grinding, packaging, and more. One-day delivery options are available through FastLane.

Wytech: A Leader in Specialty Medical Wire

Our proprietary technology and capabilities have innovated the medical wire market. Wytech's “Dead Straight” medical wire is selected for our superior torquability, and engineered wire stiffness.

How Wytech is Different

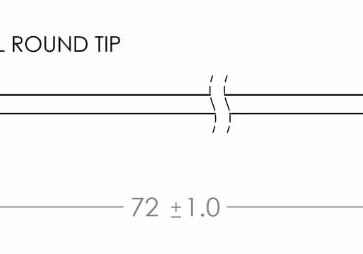

- “Dead Straight” Performance: 0.002” tolerance per inch, superior torquability, and variable wire stiffness.

- Round wire sizes from 0.003” to 0.145”

- The Unique E-Z Grind™ process reduces stress concentrations, facilitates long shallow taper grind, and reduces the requirement of heat treatment.

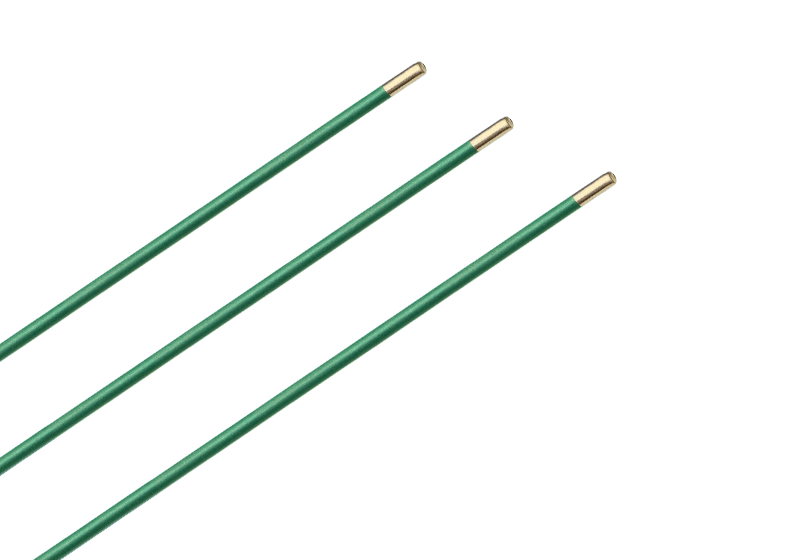

- Pre-coated PTFE wire straightening and cutting without adverse effects to the coating

- Designed to produce perfectly straight shaped wires such as “D”. “C”, and crescent-shaped.

Applications

Corewires

The corewire is used in a guidewire or an implant system and relies on accurate, clean cuts and precise straightness. Many minimally invasive procedures depend on straight guidewires to maneuver the body’s vascular system and treat or diagnose. Our ability to produce “Dead Straight” medical wire is highly valued by medical device companies.

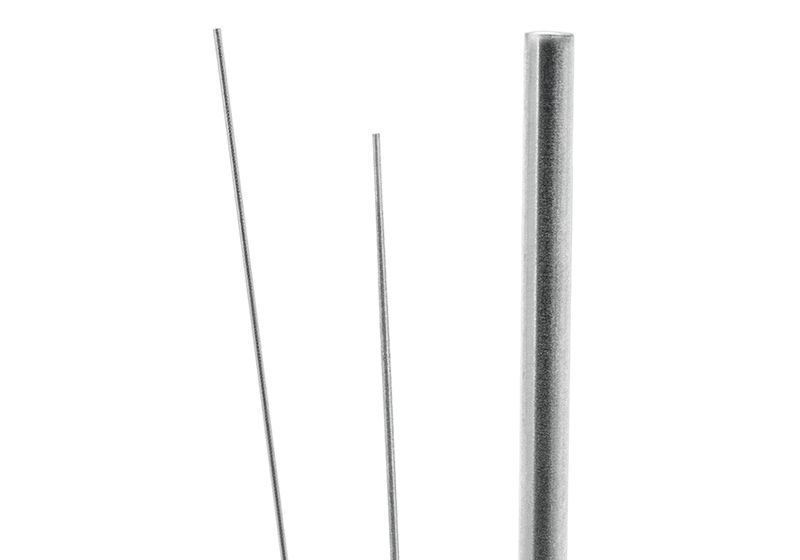

Mandrels

Mandrels are an integral part of many medical devices and medical equipment. Mandrels are used in the production of catheters and other tubes to the use of catheters and other devices that require consistent performance. Our straightening and cutting technology provides burr-free, always consistent cuts for a variety of materials and coatings. Our technology provides us the ability to produce mandrels that is precisely straight and have stiffness and flexibility for your devices.

Stylets

Stylets are used for the introduction of catheters and leads for medical procedures. Stylets need to be consistently cut and malleable based on the device’s application with burr-free ends that allow the stylet smooth movement.

Tell Us About Your Product Goals

Featured Products

The FastLane program was developed specifically to provide design engineers fast access to a wide selection of thin wall hypotubes & fine wire sizes, alloys and lubricious coatings for urgent developmental work.

- Medical Wire

- Stainless Steel, Nitinol, PTFE Coated & Parylene Coated Wire

- Diameters ranging from 0.003" - 0.145", half sizes also available

- Available in 60", 73″ and 120″ lengths

- Hypotubes

- Stainless Steel Thin Wall Metal Tubes

- Diameters ranging from 0.009" - 0.112"

- Available in various lengths

- $200 minimum order required

- COC included in each shipment

Whether it’s a product evaluation, evaluating an alternative manufacturing process, or a situation that demands delivery in four weeks, FastTrack meets your needs.

- 100% focus on mandrel and core wire development with specialized equipment and dedicated manufacturing cell

- Precision Centerless Grinding

- Catheter mandrel and core wire development

- Fast delivery, < 4 week

- Dedicated inventory of common medical wire