Medical Wire Forming

We are wire forming experts with the technology and capability to produce wire in a multitude of shapes, sizes, and medical applications. Our state-of-the-art facility and manufacturing process is second to none and allows us to help you design, develop, and produce your medical devices.

Technologies That Help You Engineer

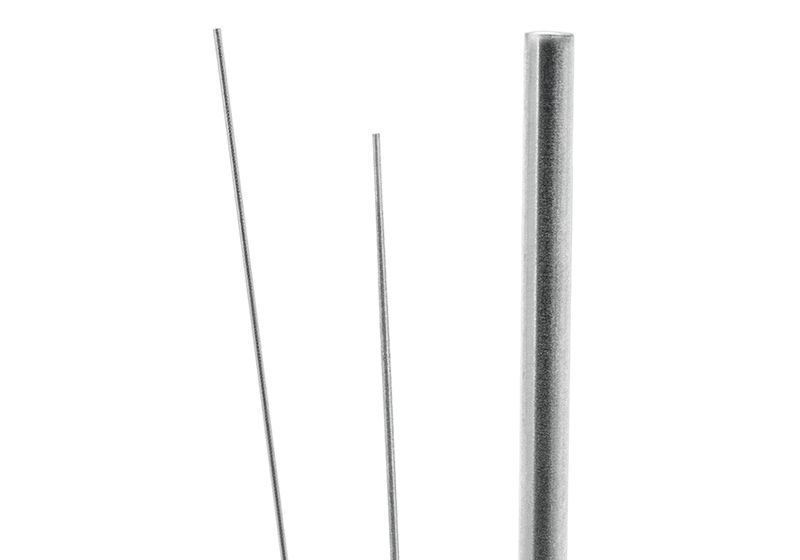

- Variety of alloys including stainless steel & nitinol

- Wire diameters as small as 0.003”

- Wire can be bent to form almost any shape

- The vertically integrated facility offers from design to product faster

Common Wire Forming Applications:

- Mandrels:

- Packaging, Bonding, Forming, Sizing, Pigtail and stylets

- Components For:

- Catheter delivery systems

- Cardiovascular implants

- Guidewires

Tell Us About Your Product Goals

Featured Products

The FastLane program was developed specifically to provide design engineers fast access to a wide selection of thin wall hypotubes & fine wire sizes, alloys and lubricious coatings for urgent developmental work.

- Medical Wire

- Stainless Steel, Nitinol, PTFE Coated & Parylene Coated Wire

- Diameters ranging from 0.003" - 0.145", half sizes also available

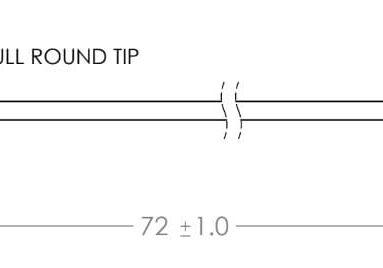

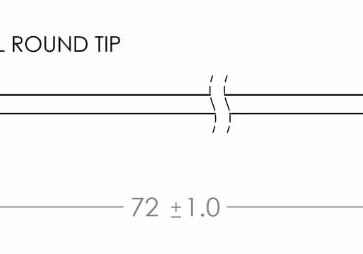

- Available in 60", 73″ and 120″ lengths

- Hypotubes

- Stainless Steel Thin Wall Metal Tubes

- Diameters ranging from 0.009" - 0.112"

- Available in various lengths

- $200 minimum order required

- COC included in each shipment

Whether it’s a product evaluation, evaluating an alternative manufacturing process, or a situation that demands delivery in four weeks, FastTrack meets your needs.

- 100% focus on mandrel and core wire development with specialized equipment and dedicated manufacturing cell

- Precision Centerless Grinding

- Catheter mandrel and core wire development

- Fast delivery, < 4 week

- Dedicated inventory of common medical wire