Advanced Surgical Medical Markets

You rely on high-quality medical wire and tubing. Wytech delivers.

From oncology to surgical robotics, the advanced surgical market is ripe for innovation. Your wire components for your advanced surgical medical devices need to be on point. The integrity of your device comes down to the quality of each component. Many wirehouses produce medical wire and tubing as part of their larger manufacturing capabilities. Wytech is different, we specialize in every aspect of medical wire and tubing production.

How Wytech Can Help with Your Advanced Surgical Device Components

Learn more about our unparalleled processes and the benefits of working with us.

Our technologies and capabilities have been perfected over the last 45 years propelling us to the forefront of the specialty medical wire market.

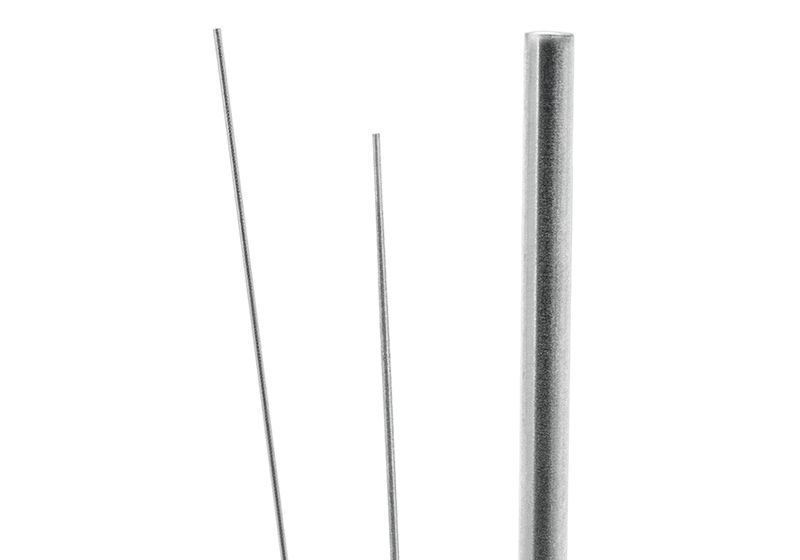

Our reputation for “Dead Straight” wire performance has enabled us to serve some of the top names in medical device development and production. Our cutting, straightening, forming, and grinding capabilities far outpace our competitors ensuring your medical device prototypes and products are accurate and precise.

Contact us to learn more about how we can help your engineer or manufacturing teams today.

The Wytech Difference is clear.

- A vertically integrated facility helps develop your specialty wire faster from design to production.

- Our proprietary technology ensures precise, accurate, and consistent medical wire & tube production providing you the components that make your device perform at its best.

- Choose from our FastLane or FastTrack programs to get the components you need faster.

- We are the leader in medical wire and tube manufacturing, we understand your needs and can help you get the components you need with minimal complications.

Surgical Robots

Ophthalmology

Ear, Nose, Throat

Orthopedics / Sports Medicine

Endoscopy

Featured Products

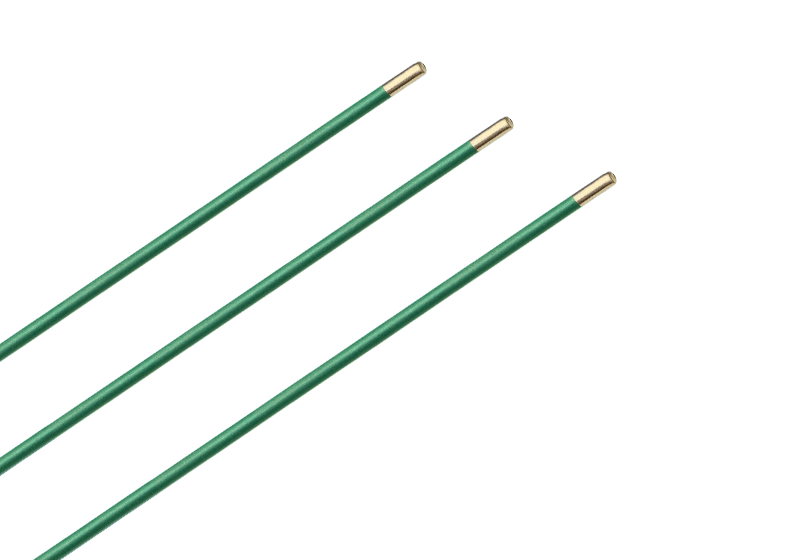

The FastLane program was developed specifically to provide design engineers fast access to a wide selection of thin wall hypotubes & fine wire sizes, alloys and lubricious coatings for urgent developmental work.

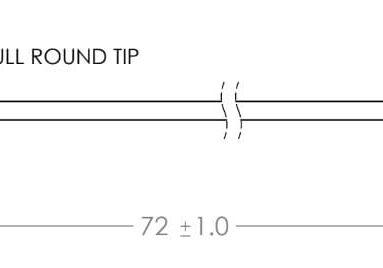

- Medical Wire

- Stainless Steel, Nitinol, PTFE Coated & Parylene Coated Wire

- Diameters ranging from 0.003" - 0.145", half sizes also available

- Available in 60", 73″ and 120″ lengths

- Hypotubes

- Stainless Steel Thin Wall Metal Tubes

- Diameters ranging from 0.009" - 0.112"

- Available in various lengths

- $200 minimum order required

- COC included in each shipment

Whether it’s a product evaluation, evaluating an alternative manufacturing process, or a situation that demands delivery in four weeks, FastTrack meets your needs.

- 100% focus on mandrel and core wire development with specialized equipment and dedicated manufacturing cell

- Precision Centerless Grinding

- Catheter mandrel and core wire development

- Fast delivery, < 4 week

- Dedicated inventory of common medical wire