Medical Wire Technologies

Wytech has spent nearly 50 years perfecting our craft at producing precise and high-quality medical wire technologies for tens of thousands of OEMs and contract manufacturers.

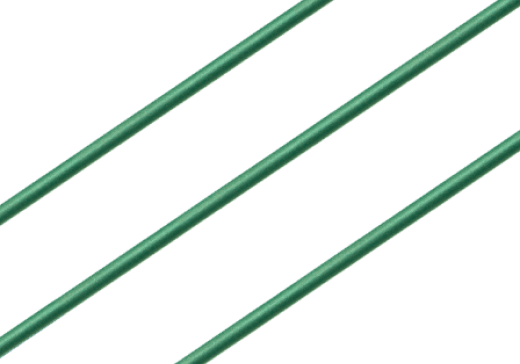

We are adept at working with multiple stainless-steel types (304v, SLT®¹), Nitinol, PTFE Coated Stainless Steel, MP35N, Inconel, hardened steels, and other medical-grade alloys.

Wytech can provide uncoated and coated metal mandrels for the following manufacturing processes: bonding, coiling, cutting, extrusion, forming, grinding, reflow, tipping & welding, packaging, and more. FastLane offers one-day delivery options.

¹SLT® is a registered trademark product of Fort Wayne Metals, Fort Wayne, Indiana.

Wytech is a Leader in Medical Wire Technology

Our vertically integrated facility combines expertise and technology to support our customers' life-saving innovations. Our engineers and manufacturing staff allow us to produce medical wire fast, letting you focus on final product design.

We provide the top medical device manufacturers with wire and tube components to advance surgical outcomes.

Featured Products

The FastLane program was developed specifically to provide design engineers fast access to a wide selection of thin wall hypotubes & fine wire sizes, alloys and lubricious coatings for urgent developmental work.

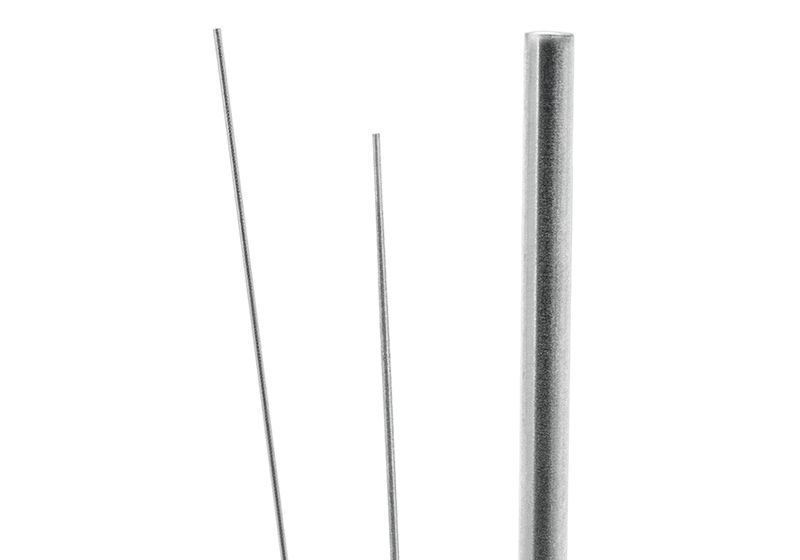

- Medical Wire

- Stainless Steel Wire & Mandrels, SLT® Type 4 and SLT® Hyten Wire and Nitinol Wire

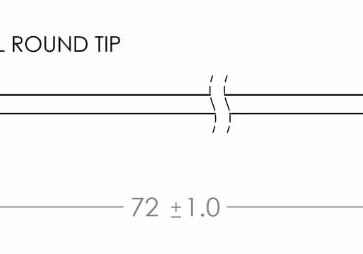

- Diameters ranging from 0.003" - 0.180", half sizes also available

- Available in 60", 73″ and 120″ lengths

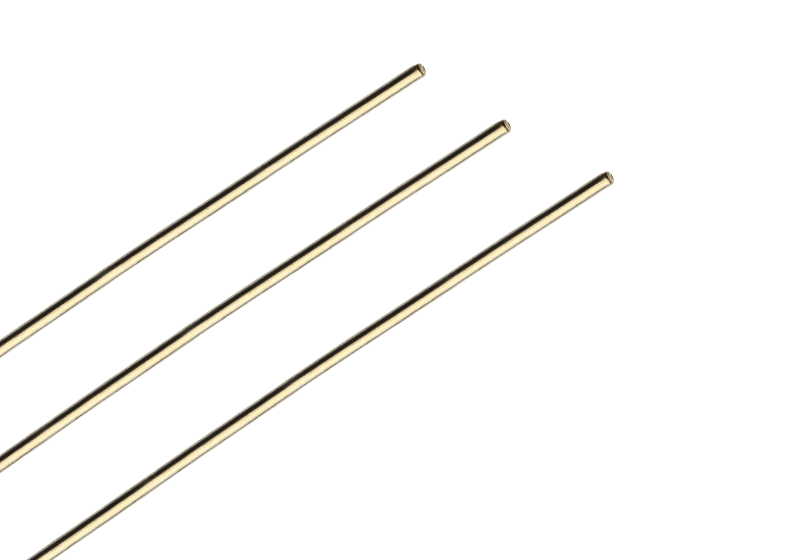

- Hypotubes

- Stainless Steel Thin Wall Metal Tubes

- Diameters ranging from 0.009" - 0.112"

- Available in various lengths

- Packaging Mandrels

- Trocars

- $200 minimum order required

- COC included in each shipment

Whether it’s a product evaluation, evaluating an alternative manufacturing process, or a situation that demands delivery in four weeks, FastTrack meets your needs.

- 100% focus on mandrel and core wire development with specialized equipment and dedicated manufacturing cell

- Precision Centerless Grinding

- Catheter mandrel and core wire development

- Two week delivery

- Dedicated inventory of common medical wire