Laser Processing

Wytech recognizes the high-performance benefits of laser processing – versatility, high level of repeatability, efficient process speeds.

Our CNC 6-axis laser cutting micromachining system is ideal for complex cut geometries on hypotubing, non-contact laser knurling, hole popping, and more. Dimensional precision and short cycle times are assured with this advanced machining center.

Cutting

- Part Diameter Range: .25-8mm, Up to 3m long

- Accuracy: ≤ +/- 15 micron

- Repeatability: ≤ +/- 5 micron

- Cutting Speed: We’ve routinely cut >1000mm/s

Marking

- Laser marking applications include:

- Part number identification

- Positioning locator

- Barcodes

- Benefits of laser marking over pad printing:

- Non-contact with little heat input, discoloration, or oxidation

- Depth marking, etched, laser

Welding

- Welding applications include

- Spot welding

- Seam welding

- Benefits of Rotational CNC laser welding:

- Accuracy of component mating for precision applications

- Repeatability & scalability for high volume applications

Tell Us About Your Product Goals

Featured Products

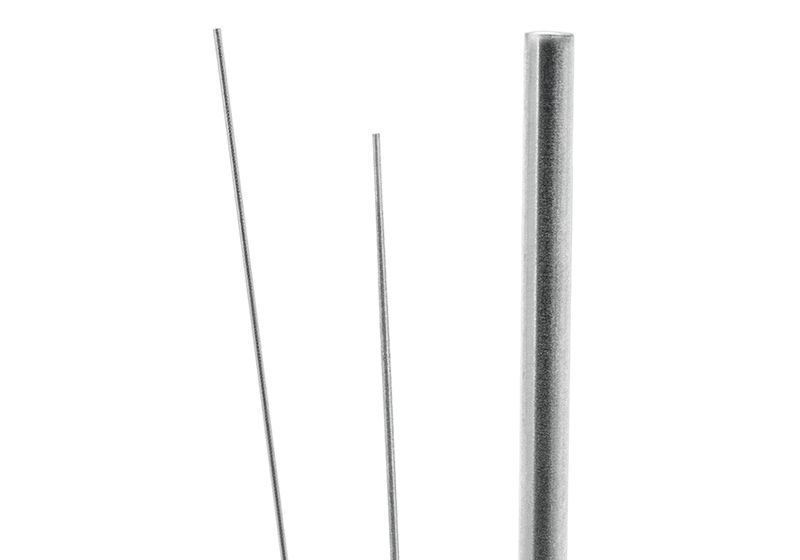

0.0475″ X 73.0″ Nitinol Wire

Nitinol SEA, .0475 +/-.0004 X 73.000 +/-.250, C’less Ground Surface

$62.50

The FastLane program was developed specifically to provide design engineers fast access to a wide selection of thin wall hypotubes & fine wire sizes, alloys and lubricious coatings for urgent developmental work.

- Medical Wire

- Stainless Steel Wire & Mandrels, SLT® Type 4 and SLT® Hyten Wire and Nitinol Wire

- Diameters ranging from 0.003" - 0.180", half sizes also available

- Available in 60", 73″ and 120″ lengths

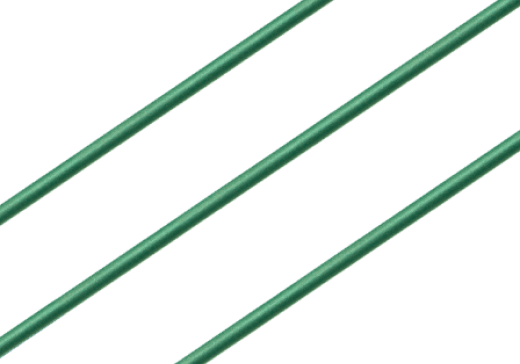

- Hypotubes

- Stainless Steel Thin Wall Metal Tubes

- Diameters ranging from 0.009" - 0.112"

- Available in various lengths

- Packaging Mandrels

- Trocars

- $200 minimum order required

- COC included in each shipment

Whether it’s a product evaluation, evaluating an alternative manufacturing process, or a situation that demands delivery in four weeks, FastTrack meets your needs.

- 100% focus on mandrel and core wire development with specialized equipment and dedicated manufacturing cell

- Precision Centerless Grinding

- Catheter mandrel and core wire development

- Two week delivery

- Dedicated inventory of common medical wire