What is FastTrack?

Let us accelerate your catheter mandrel or core wire application by delivering custom critical ground wires in less than 4 weeks.

With decades of wire grinding know-how and commitment to collaboration, FastTrack will provide design for manufacturing feedback along with your prototyped medical wire designs. Our customers may also rent equipment time and embed with our experts at Wytech for up to a week for real-time design iterations.

FastTrack Rapid Prototyping Program

Wytech's experienced technical team is the heart of our FastTrack program and is passionate about collaborating with our customers whose products span across interventional and minimally invasive surgical markets. We work diligently to identify and understand your ground catheter mandrel or core wire design, to deliver custom medical wires and application performance needs.

- Purpose: Catheter mandrel and core wire development

- Dedicated Centerless Grinding, Stamping, and End Treatment Equipment and Technicians

- Fast delivery, < 4 weeks

- Dedicated inventory of Stainless Steel and Nitinol medical wire (including PTFE coated)

Why Choose FastTrack for your ground catheter mandrel, wire and metal tubing grinding needs?

Discover how Wytech's technical excellence, in-house material experts, and advanced precision grinding capabilities can elevate your R&D project's success.

- Materials

- Uncoated Stainless Steel Types (304v, SLT)

- PTFE Coated Stainless Steel

- Hardened Stainless (June 2024)

- Nitinol

- MP35N

- Inconel

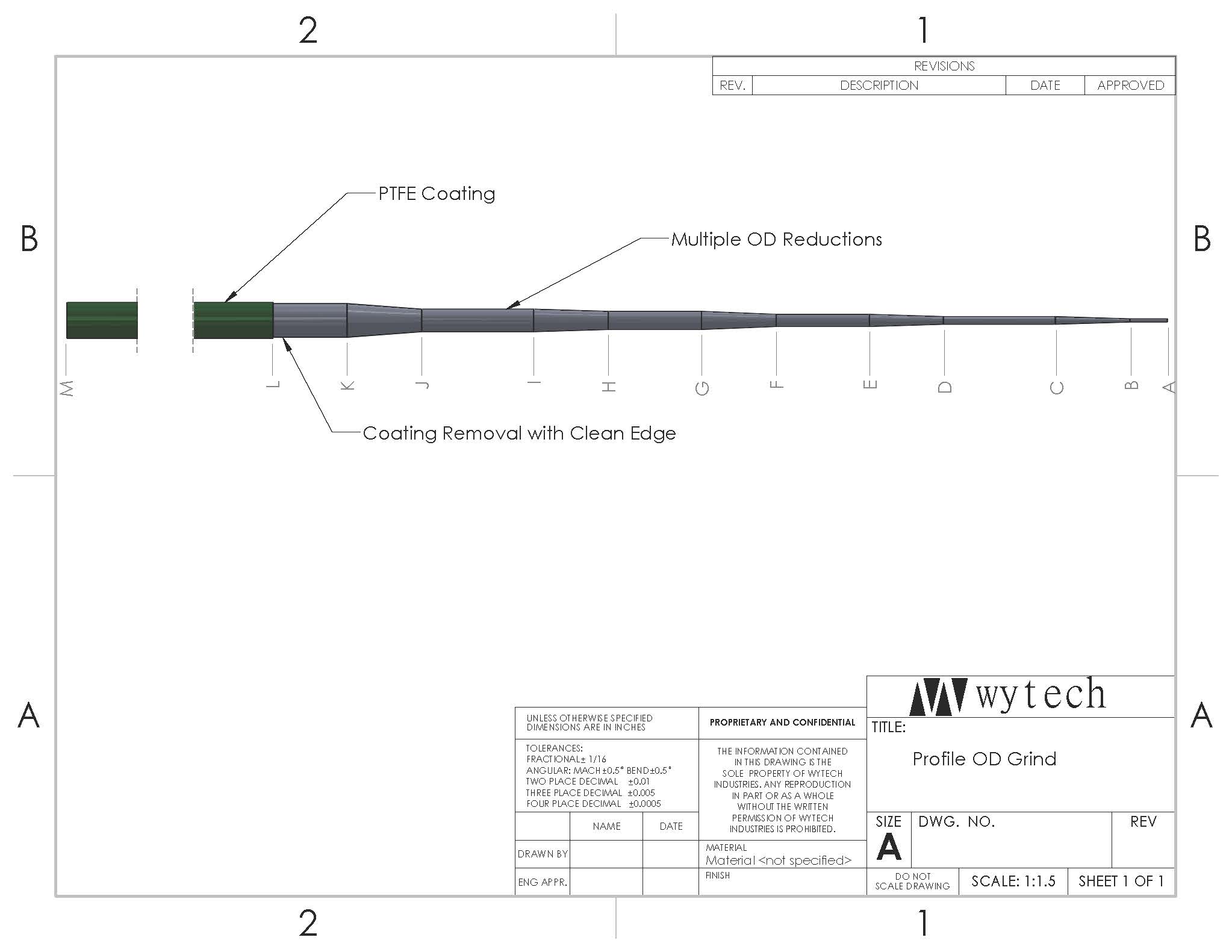

- Precision Ground Tapers and Profiles

- Blivets

- Flats

- Micro Grinds

- Notches

- Single / Multiple Tapers

- Stepped

- Features & Tolerances

- Fine Wire Grinding

- 0.038" - 0.002"

- Intermediate Wire Grinding

- 0.106" - 0.038"

- Large Diameter Grinding

- 0.300"(+) - 0.106"

- Fine Wire Grinding

- Proprietary grinding know-how to achieve complex grind profile

- Proprietary stress relieving process to improve wire’s mechanical properties

- Proprietary coating removal technologies for improved design freedom

How it

Works

1. Engineering Expertise

Specify and confirm your critical dimensions & tolerances.

2. Cost Review

Quotes will be provided within 48 hours.

3. Lead Time

Leveraging FastLane raw material inventory allows for delivery within 4 weeks.

4. Documentation

Inspection data and Material Certifications provided.

I am very happy with the service that Wytech Fastlane Provides.

Any time I’ve requested material, the quoting service is very quick and the lead times are very convenient.