Precision Grinding

Wytech’s robust precision grinding technologies have been perfected for nearly 50 years. Our state of the art equipment allows us to meet our customers custom grind configurations and challenging tolerance needs.

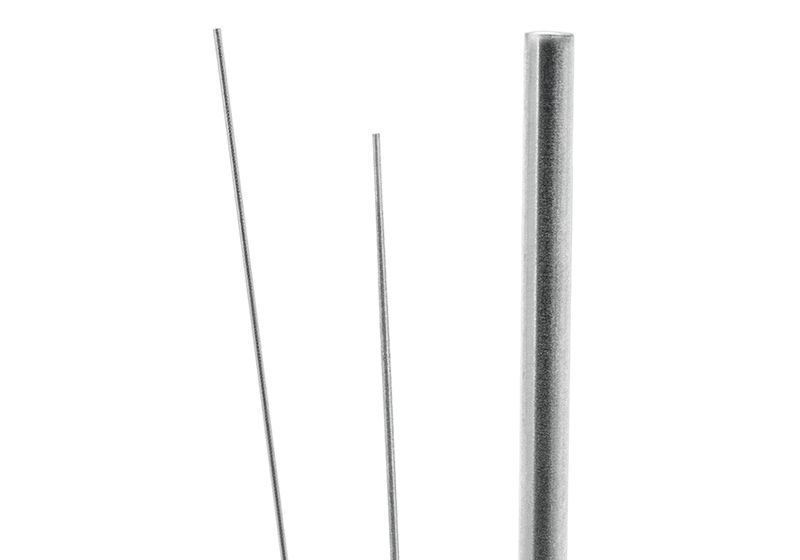

- Centerless Grinding

- Electro-Chemical Grinding

- Point Grinding

We are adept at working with multiple stainless-steel types, nitinol, and other medical-grade alloys.

Advanced Precision Grinding Features

- Applications: PTCA and Neurovascular Guidewires, implant delivery systems, processing mandrels

- Typical Grind Profiles: multi-taper, paddle, plunge for special mandrels, and skiving

- Ground features: shape flats, threads, bumps, arcs, hexes, balls, ellipses, and concave/convex radii.

- In-house annealing and stress-relieving for maximum flexibility in processing

- Linear tolerances as precise as +/- 0.001”

- OD diameters as small as .002"

Wytech specializes in precision grinding and machining solutions for complex geometry mandrels used as catheter manufacturing aids and tools ranging from various applications, including reflow to bonding, cutting, tipping, and welding.

Combined with our sister company, Mountain Manufacturing Technologies, we are your single source for R&D mandrels and production mandrels.

Wytech has the technical experts to assist in the design of mandrels, core wires, and guidewires utilizing stainless steel and nitinol. We have dedicated development equipment for rapid prototyping.

We offer a wide variety of precision grinding options to best meet many applications.

Wytech offers a variety of precision grinding configurations:

- Flat grinds

- Micro grinds

- OD grinds

- Paddle grinds

- Plunge grinds

- Point grind

- Profile grinds

- Step grinds

- Taper grinds

Wytech’s proprietary 5-Axis systems produce point ground tips such as Menghini features scalloped tubes with varying grind angles for biopsy, aspirator needle sets.

Grinding / Skiving

Skiving and grinding features are produced typically on Hypotubes to allow for a smooth transition for the tube flexibility in guidewire and catheter assemblies.

Tell Us About Your Product Goals

Featured Products

The FastLane program was developed specifically to provide design engineers fast access to a wide selection of thin wall hypotubes & fine wire sizes, alloys and lubricious coatings for urgent developmental work.

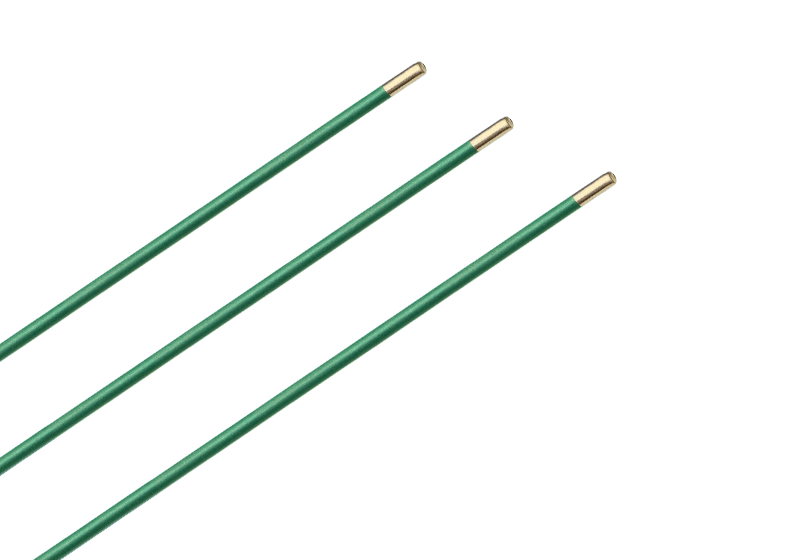

- Medical Wire

- Stainless Steel, Nitinol, PTFE Coated & Parylene Coated Wire

- Diameters ranging from 0.003" - 0.145", half sizes also available

- Available in 60", 73″ and 120″ lengths

- Hypotubes

- Stainless Steel Thin Wall Metal Tubes

- Diameters ranging from 0.009" - 0.112"

- Available in various lengths

- $200 minimum order required

- COC included in each shipment

Whether it’s a product evaluation, evaluating an alternative manufacturing process, or a situation that demands delivery in four weeks, FastTrack meets your needs.

- 100% focus on mandrel and core wire development with specialized equipment and dedicated manufacturing cell

- Precision Centerless Grinding

- Catheter mandrel and core wire development

- Fast delivery, < 4 week

- Dedicated inventory of common medical wire